Process Heater Case Study

Project Details

Customer Name: Centrica Storage

The Brief: Provide heat for Rough storage field offshore rig

Location of Installation: Rough Platform

Products supplied: Water/Glycol Process Heater

Project Duration: Typically 9 months

The Solution

Process Combustion was selected to provide a replacement heating medium heater for use on the Rough Storage off shore rig. The heater provides heat to the rig and for gas storage.

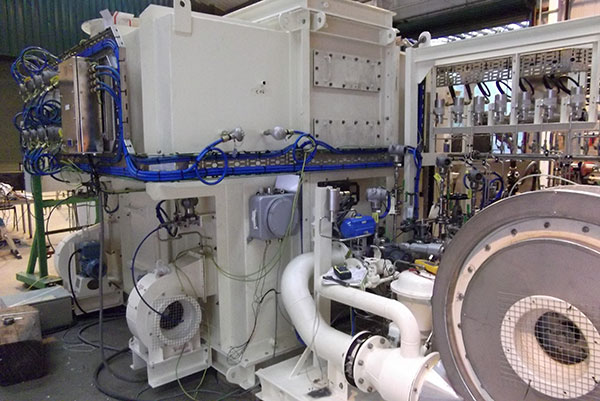

- The Process Combustion convective process heater is a lightweight, ceramic fibre lined, direct fired, forced draught cabin style heater. This design has also been used for regeneration gas heaters and for nitrogen vaporiser units for the nuclear industry.

- The equipment supplied by Process Combustion included the heater casing, tube bundle, dual fuel burner (natural gas and diesel), combustion air blower and dilution air blowers, gas and diesel control trains and PLC control system. All equipment was supplied in accordance with latest combustion standards and to Centrica’s specifications.

Related Case Studies